Bespoke Automation Solutions

Combining our engineering expertise and innovative thinking approach we have delivered many industry firsts in bespoke automation solutions.

–Viioni makes the difference.

Bespoke Automation Solutions

At Viioni, we thrive on challenges! Our clients, across every sector, come to us with extremely complex problems. Our vast experience within the automation industry allows us to design and implement innovative technology solutions, enabling us to conquer these extreme problems and supply our customers with the ultimate bespoke automation solutions system.

From the fastest automatic box opener for random size cases, to producing the first to market automatic tiling cell in the construction industry, to an automated glass handling and storage system. We excel in developing new ways of utilising the latest technologies and automation to deliver solutions that make the difference.

Below are a few examples of our experience, in producing leading edge automation technology.

Automatic Box Opener

Our team were challenged with finding a faster, safer and more efficient way of opening random size cardboard boxes which were being delivered to a warehouse, daily.

Boxes are inducted into the fully guarded automatic box opener conveyor system. Upon entry to the cell, inline dimensioning technology is utilised to measure the length, height and width of the box.

Computing these dimensions, the blade positions and adjusts itself automatically, to the correct positioning for cutting. The box is then driven through the first cutting zone, cutting the box on two sides before it is transferred at 90 degrees, to cut the remaining two sides.

The box opener handles a range of box dimensions from 700mm x 700mm x 700mm to 100mm x 100mm x 100mm at a rate of up to 1,500 boxes per hour.

Glass Processing and Storage Line

Our team have designed and developed a fully automated glass handling and storage line capable of storing up to 1,000 units of glass.

The system includes vertical conveyors designed specifically for safe glass handling and a servo driven, automatic storage and retrieval system for accurate product put away. Combined with our in-house developed software modules, the system offers complete accuracy and trace ability for all units throughout the process.

Additional modules such as glass cutting optimisation software; 90-degree transfers and robotic loading and unloading can easily be added if necessary.

Through working with our clients in close partnership, we develop ideal bespoke automation solutions that meet your needs and takes your business to the next level.

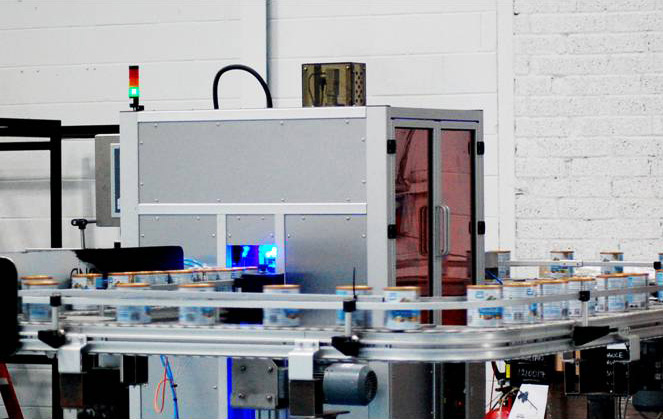

Validation Tunnel

Our team were challenged with finding a bespoke automation solution to perform a 360-degree scan of cylindrical cans running at 400 cans per minute. The system was also required to verify lid placement and lid colour while reducing change over time between product runs.

This bespoke automation solution utilises seven cameras mounted on linear drives with an automatic two-level rejection system and offers customers full product verification with zero shipping errors.

Changeover time between products is reduced from hours to minutes as a simple scan of the new product signalled the cameras to automatically adjust to a new height position for the next can size without needing to recalibrate the cameras.

If you have any new automation challenges that you would wish to discuss please give one of our engineers a call now.

Contact us

Tel: 44 (0) 28 9692 8400

Email: info@viioni.com