Viioni with FlowSort Modular Sorting Systems

Learn More

Sortation At Up To 10,000 Parts Per Hour

Viioni offer a modular sorting system built up out of standard modules which makes it possible to configure your own sorting line configured to your own needs. With FlowSort Modular Sorting Systems, Viioni deliver 24V driven diverters and 48V Servo drivensorter modules which can be built into an aluminium profile frame especially designed to suit the standard sort modules. It is also possible to easily

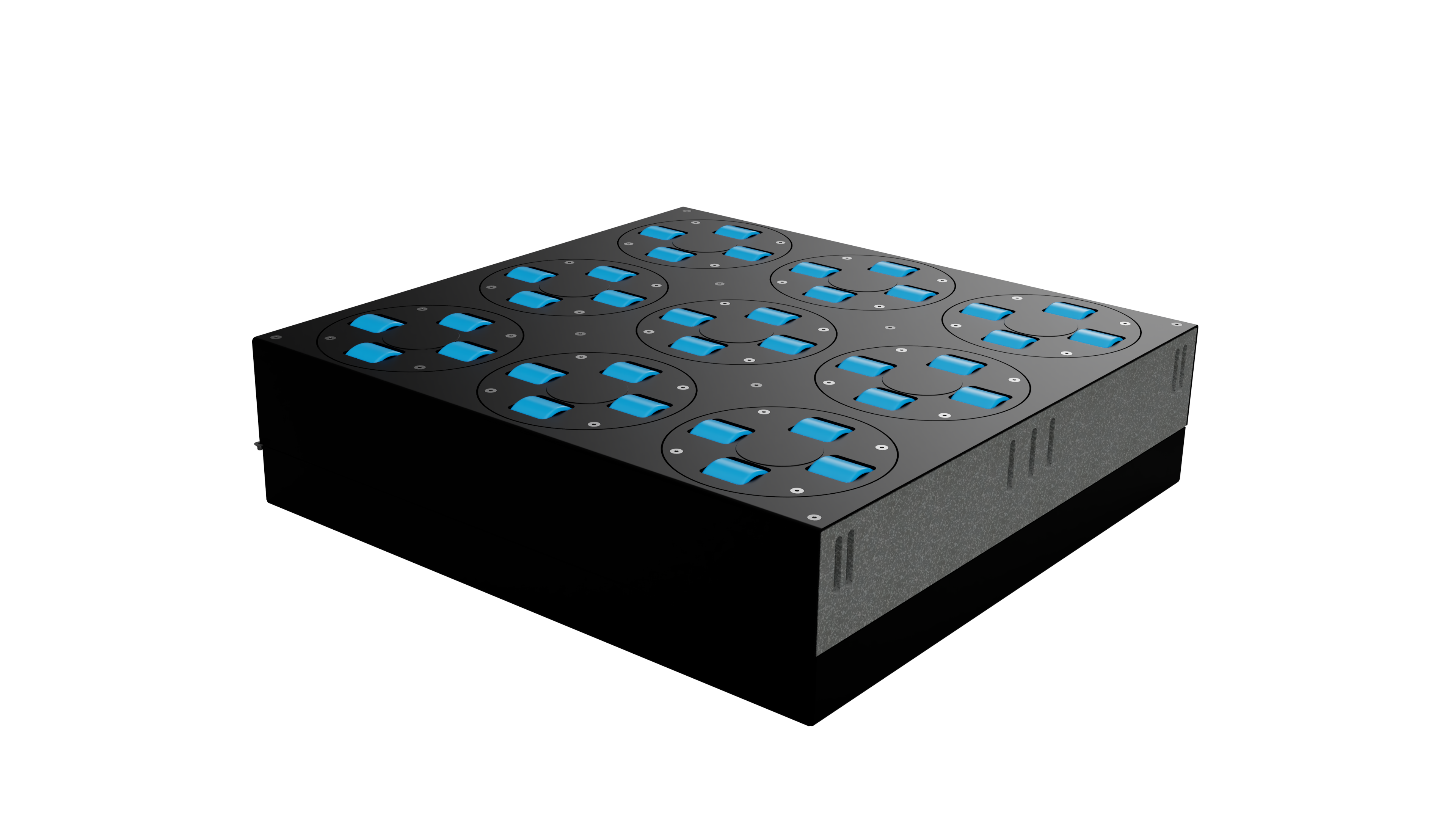

TwistSorter TS-24

The TS-24 sorter is a 24V high speed modular sorter line, which you can configure to your demand, all produced as a plug & play system. If you need more sorting points behind each other, simply connect them and configure them the way you want, with the exits you want. If you need a belt module in front to make a gap, you can connect them into the line and connect it. If you need a belt module in between sorting points, you just move the sorting points out from each other and place the belt module in between and connect it, all plug & play offering greater flexibility for future expansion. Servicing is made easy by removing the wheel from the top with a quick release principle.

TwistSorter TS-48

The TS-48 sorter is a 48V high speed modular sorter line, which you can configure to your demand. The Intelligent modular sorting application is intended for use in logistic systems, mainly in the post & parcel industry. The application consists of at least one main cabinet with the Master CPU and HMI (both SigmaControl) to power on and control one or more slaves by a Varaan bus-system. Each slave can control up to 6 servo-based sorting-rows containing 2 to 5 rotating wheels all driven by 1 servobased transport-motor. This leads to adjustable reliable speeds and exact sensor-controlled time-based separation of boxes and envelopes. Optional Sensors on the outputs can give a “full” signal or a fault when a box was expected. The Master can communicate with a WMS based on several networks as (optional) Profinet, Ethernet to enter the box-data, such as weight, dimensions and output positions.

Key Facts & Benefits

- “Ready to run” solution to control a multi belt/sorting system

- Easily scalable for future expansion

- Modular concept, each unit has its own 24VDC Power-supplies and servo-controllers and only needs 230VAC power supply and a Varaan Bus communication-cable

- Low Maintenance costs

- Number of belts and stations only limited by used CPU type

- Collision monitoring

- Easy diagnostics

- Easy mounting sort module with easy plugin connections

If you have any new automation challenges that you would wish to discuss please give one of our engineers a call now.

Contact us

Tel: 44 (0) 28 9692 8400

Email: info@viioni.com