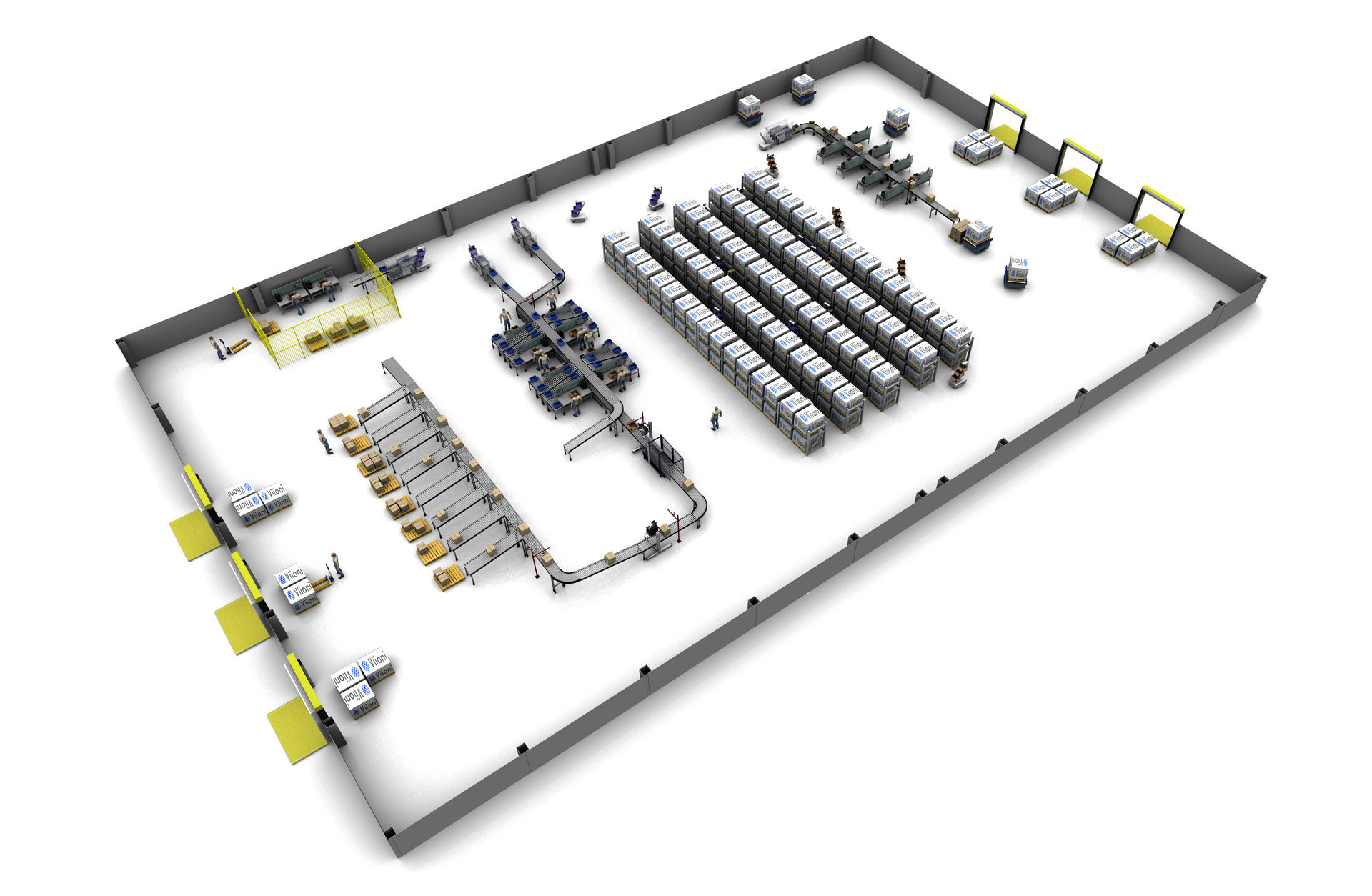

Turnkey Fulfilment Solutions

Our vast experience and skills will help in providing turnkey solutions.

–

Turnkey Fulfilment Solutions

Viioni’s approach with our clients is to develop and establish a robust working partnership, resulting in us designing and implementing the ideal automation solution for your business needs.

Upon listening to your processes, problems, bottlenecks and goals, we then apply our experience and skills to develop the perfect turnkey fulfilment solution.

With so many key decisions to be made we will work with you to find the right conveyor, labeler, scanner, sorter, robot, checkweigher, picking device and much more.

All design elements are brought together with the Viioni WMS system, maximising productivity, efficiencies and reducing unnecessary labour costs.

Project Implementation

Our project team works hand in hand with our clients, ensuring all projects have a smooth implementation, transition and training period. From the start of the project through FAT, to installation and go live, our team will be there to take control.

We understand that it is vital our client’s business to run uninterrupted during the project implementation stage. By working closely and understanding our client’s needs, enables us to provide a thorough step by step project and implementation plan, full training and documentation.

Our team will remain on site throughout the transition period, to manage the system ramp up and ensure your team are comfortable with your new system and its operation. Our automation turnkey fulfilment solutions combined with our Viioni WMS system and fully supported by our experienced engineers, means we offer state of the art advanced automation, which delivers optimum results.

All items received into warehouse through use of Viioni Receiving software module with single scan check in available at pallet, case or item level.

Returns

Processing of returned goods aided and verified through use of Viioni Returns Software module. Automatic Box Cutter available for quick and safe opening of random size cases

Putaway

All items verified by barcode scan and ViiPros utilised to deliver stock to correct location reducing operator walk time. Automatic stock putaway available in totes, cartons or pallets.

Order Optimisation

Viioni Picking software generates the most optimum picking routes for the ViiPros releasing orders in waves to maximise efficiency and meet business requirements

Picking with ViiPro

ViiPro’s utilised to maximise productivity within the picking process as well as offering pick verification at the pick. Orders picked to carton/tote dependant on business needs

Docking Station

Once all orders are picked, ViiPro loads totes/cartons into the docking station for automatic transport to packing

Pack Station

Totes delivered to available pack benches where operators pack orders to most optimum packaging as determined by Viioni Carton Optimisation software.

Manifesting

Shipping documentation is produced before cartons are automatically closed, sealed, size reduced, weighed, dimensioned and labelled ready for shipping

Ship Sortation

Completed orders are sorted based on shipping requirements, e.g. By location, by size, by pallet, by container etc.

Quality Control

ViiPros deliver selected orders or high value items to designated area for additional QC checks if required.

Contact us

Tel: 44 (0) 28 9692 8400

Email: info@viioni.com