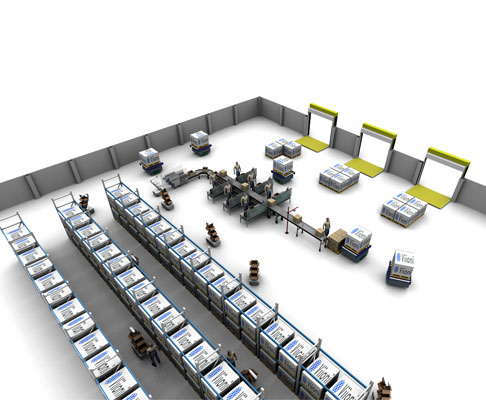

The ViiPro Warehouse Automation Robot

Introducing your newest employee; transforming warehouse automation with the latest warehouse automation robot.Viioni make the difference.

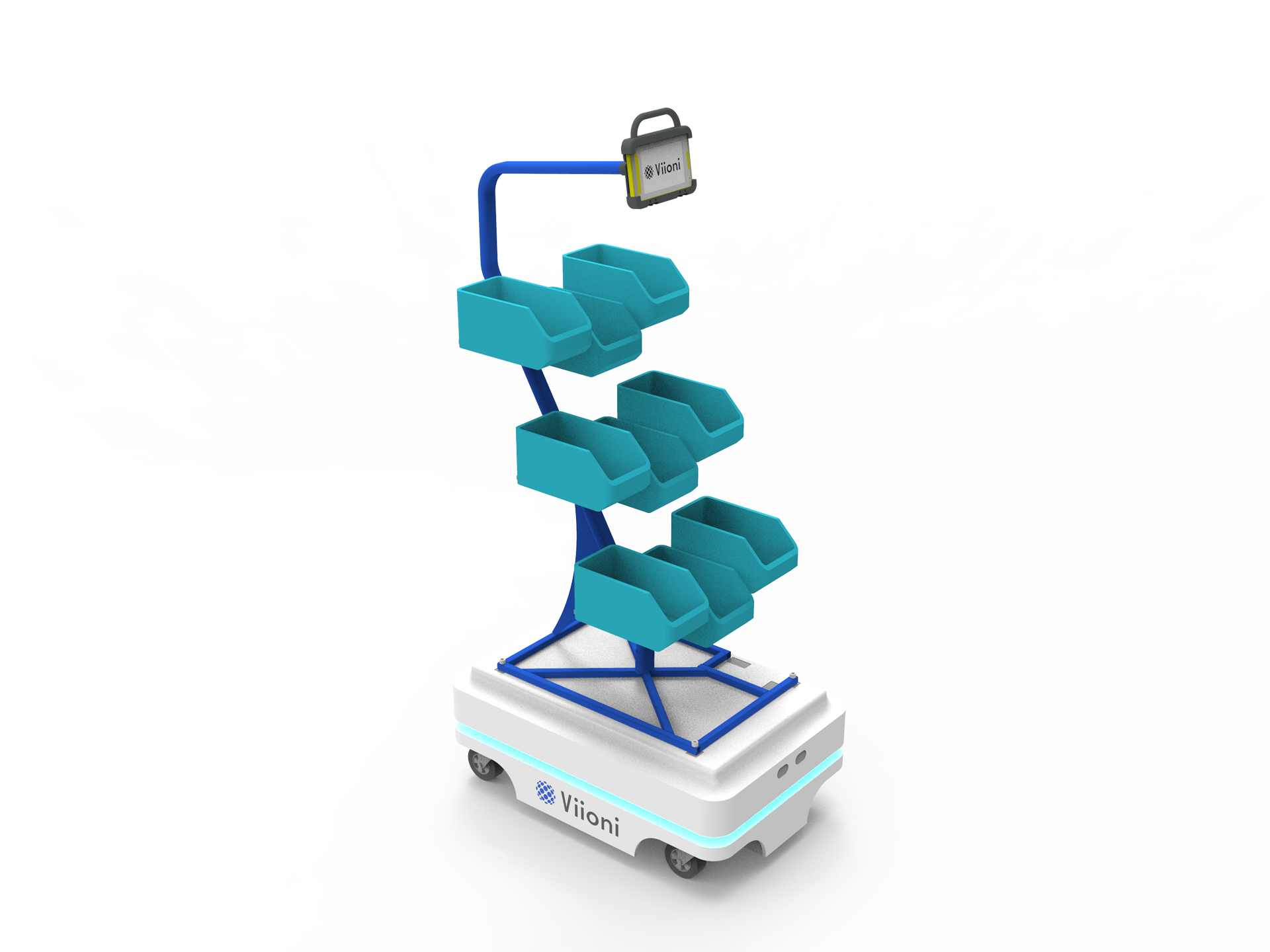

Viipro Tote

Viipro Small Picks

Viipro Case/Box Pick

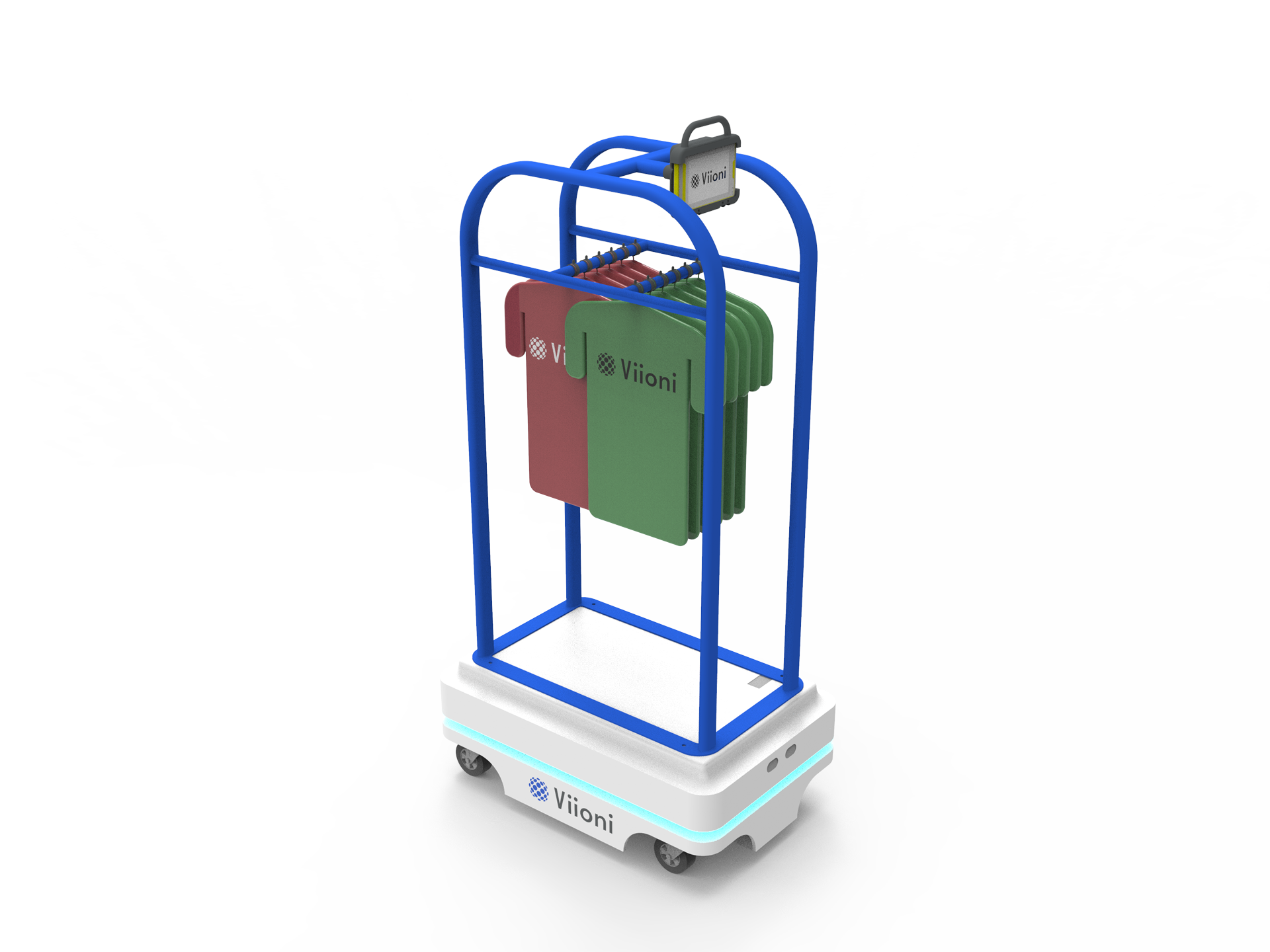

Viipro Garments

Viipro Bottle Picks

Viipro Pick To Carton

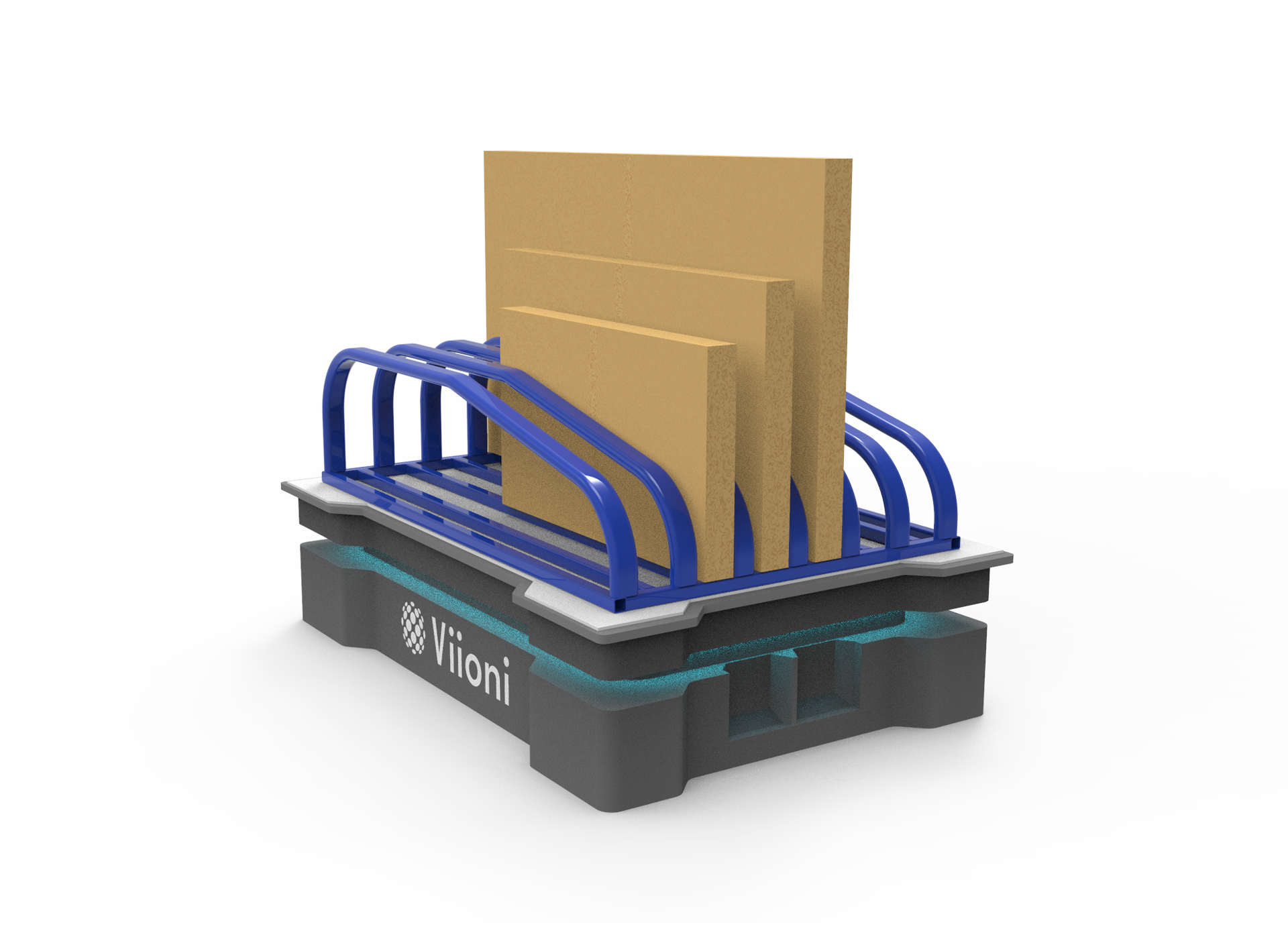

Viipro Pick To Pallet

.

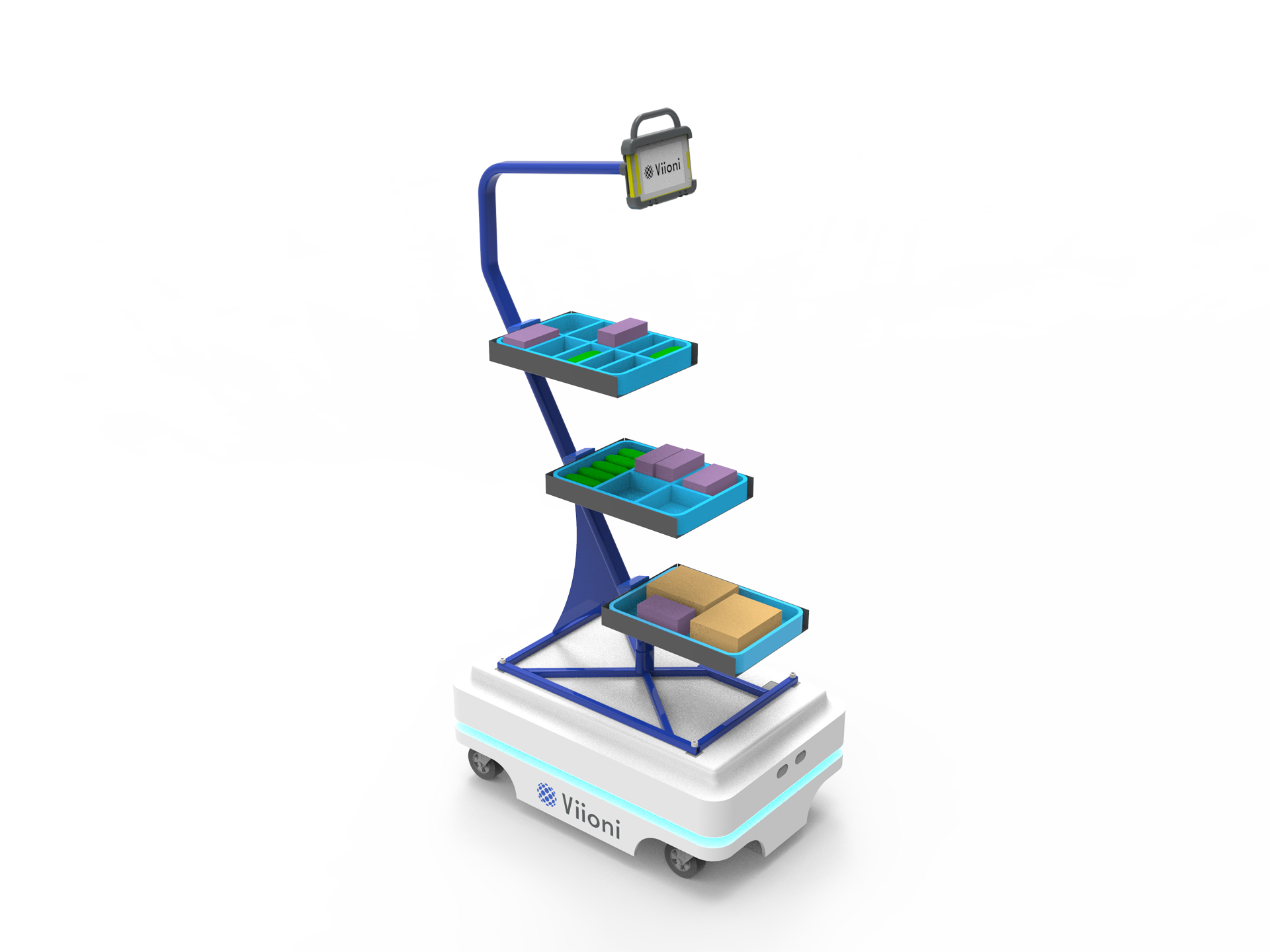

Viipro Trays

Viipro Electronics

.

The Viioni ViiPro

The Viioni ViiPro is transforming the world of warehouse automation robots. Our new generation of autonomous mobile picking robot aids operators in the picking process.

This latest model of warehouse automation robot minimises operator walk time, allowing employees to focus on higher value add tasks, optimising your company’s productivity. ViiPro, along with the Viioni receiving and manifesting system, means less walk time carrying boxes through warehouses.

The ViiPro navigates through the warehouse autonomously without the need of any guiding tracks to be laid. Our systems provide greater flexibility and effective use of space within a busy warehouse.

No more need for aisle blocking conveyor systems.

How it works

The ViiPro enables operators to be more efficient, productive and accurate throughout the order picking process. Upon receiving a set of orders from the Viioni WMS system, the ViiPro determines the optimum route through the warehouse to fulfil orders.

Operators are simply responsible for completing picks for all ViiPros that arrive within their designated zone thus minimising walk times between picks. This eliminates employees walk time between transferring picked orders from the pick zone to the despatch/packing zone.

By utilising our built-in verification scanner, pickers can verify a correct pick at the pick zone. This eliminates incorrect pick errors, saving companies’ time and costs while increasing overall the client’s productivity and profitability. Image based picking aids such as tablets showing the product, assist the operator especially with non-barcoded items.

The 3-tier system allows for multiple orders to be picked simultaneously again adding to the productivity of the system. The Viioni software optimises the release of orders to ensure a continuous and consistent workflow for all pickers.

Pick to Tote

Pick to tote offers a dedicated packing function with a ‘one size fits all’ approach to order picking allowing operators to focus solely on the pick. The ViiPro warehouse automation robot delivers completed totes to pack stations where the Viioni manifesting software is utilised for packing, documentation and shipping.

Multi Order Consolidation

Through the Viioni optimisation software, multiple single line orders can be consolidated increasing productivity and efficiency within the warehouse. Single totes can be assigned to multiple single item orders which is particularly beneficial within the ecommerce industry.

Pick to carton

The ViiPro’s pick to carton solution essentially enables operators to pick and pack simultaneously. As the autonomous mobile robot travels through the warehouse, pickers pick items directly to the carton ready for shipping. Once orders are complete the ViiPro delivers the open carton to the manifesting area where the order is completed without the need for additional packing stations.

Pick to Pallet

The ViiPro Pallet solution allows for operators to pick full cases to pallets ready for shipping. The ViiPro Pallet is capable of pick up, transport and unloading of pallets up to 500kg. Once all orders are complete the pallet is automatically delivered to the shipping area ready for processing.

ViiPro Docking Station

The ViiPro docking stations allow for totes/cartons to be automatically transferred from the ViiPro to an automated manifesting system. These stations are also used for automatically retrieving empty totes for the next order or for retrieving totes/products to be put away. Re-assignment of orders to empty totes are done at this station prior to the ViiPro being released for the next waves of picks.

Receiving Put away & Replenishment

An autonomous mobile robot can also be utilised for delivering stock to the correct area of the warehouse. Product can be put away in totes or original packaging. This eliminates walking time for replenishing stock, also stock can be replenished simultaneously with live picking. This method is ergonomically safer and optimises the put away process.

Auto De-Trash

ViiPros eliminates the problem of waste cardboard clogging up aisles and shelves. The ViiPro hook automatically removes full cages from the picking area and delivers to the waste disposal point within a company’s warehouse. This saves significant walk time within a busy warehouse as well as eliminating the need for expensive overhead trash conveyors, which are known to continuously get jammed causing down time.

Product to Man

ViiPros can be utilised within manufacturing and assembly lines for replenishment of stock. The Viioni system is alerted when there is low stock at any assembly station and stock is automatically delivered to this station. This eliminates the need for operators to leave their station to retrieve parts, thus optimising productivity and efficiency.

Ease of Implementation

Unlike the more traditional conveyor-based warehouse systems, the Viioni ViiPro allows for rapid installation within a matter of days as opposed to months with minimal disruption to your business.

The ViiPro’s simple to use mapping interface enables rapid learning of the warehouse environment which allows the complete Viioni fleet to optimise picking routes.

There is no more need to change or move racking, as the Viioni system can operate within your current warehouse layout greatly reducing implementation costs.

Peak times no longer an issue

Events like Black Friday, Cyber Monday or new product releases need no longer be an operational concern.

Simply add additional ViiPros to your warehouse as and when needed.

Autonomouse robots can be very simply be added to the fleet through the user interface without the need of any additional mapping or training.

Contact us

Tel: 44 (0) 28 9692 8400

Email: info@viioni.com